Get clarity into the condition of your assets across your portfolio.

AlphaX ingests operational data from a variety of IoT, control systems and other sources to monitor the condition and performance of your assets. The condition monitoring solution scales from one asset to entire processes or even hundreds of remote sites spread across geographical regions and borders. Outputs from the AlphaX Condition Monitoring software are used to trigger actions such as repair alerts and alarms, immediate safety intervention using edge devices and integrated with other enterprise systems using web services for visibility across your entire portfolio.

Alerts and Notifications

Getting notified of critical events in your operation is essential in today’s modern operations. Managers and shareholders expect you to know exactly when and where events take place and what’s the impact to the bottom line.

With AlphaX, you can set as many alerts and alarms as you need to manage your operation. The platform has the ability to set multiple levels and multiple conditions per alarm so the system automatically escalates as the events take place, and to set active times so you can eliminate those nuisance alarms in the middle of the night.

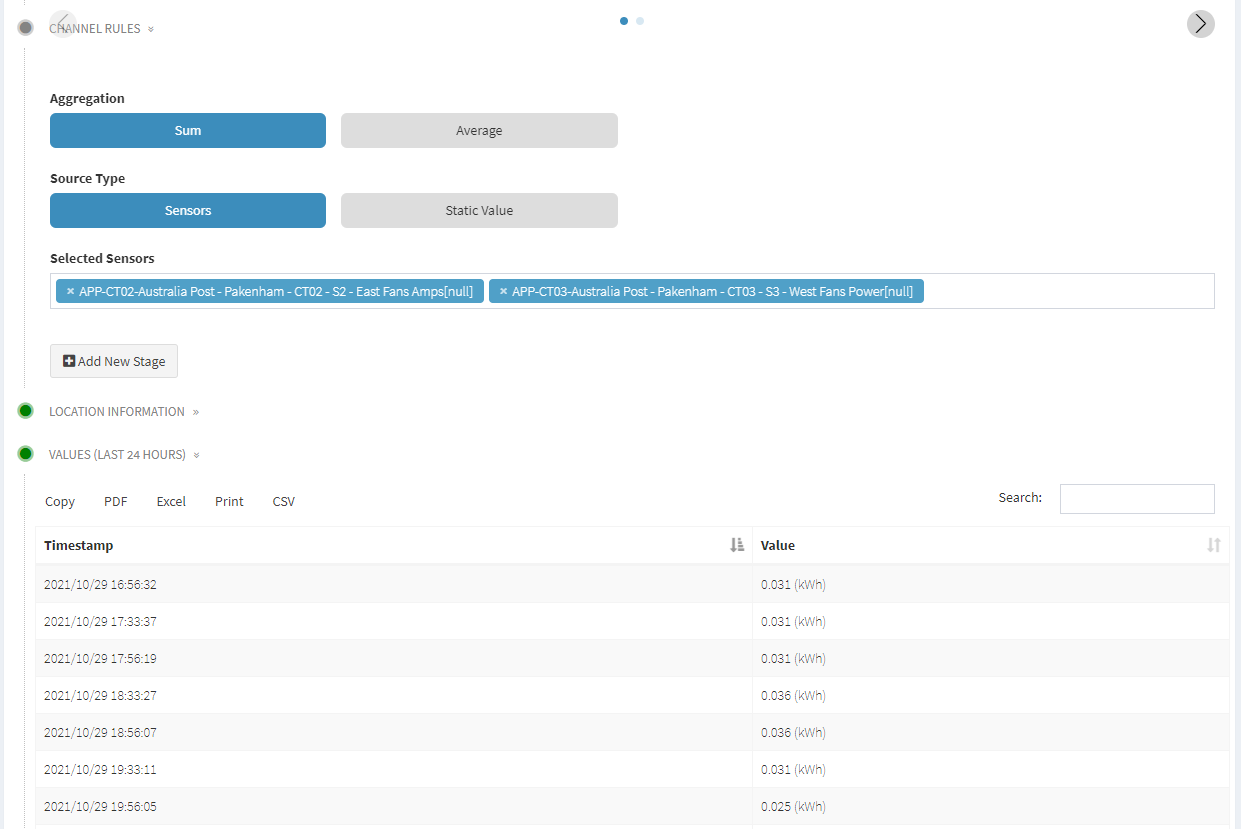

Perform Calculations

Built into AlphaX is a powerful calculation engine that provides the ability to create “software” or virtual data points. In just a few clicks, these data points can calculate in real time and used in Predictive Analytics models allowing for powerful flexibility and the ability to turn complex scenarios into a simple metric – think asset condition monitoring health score.

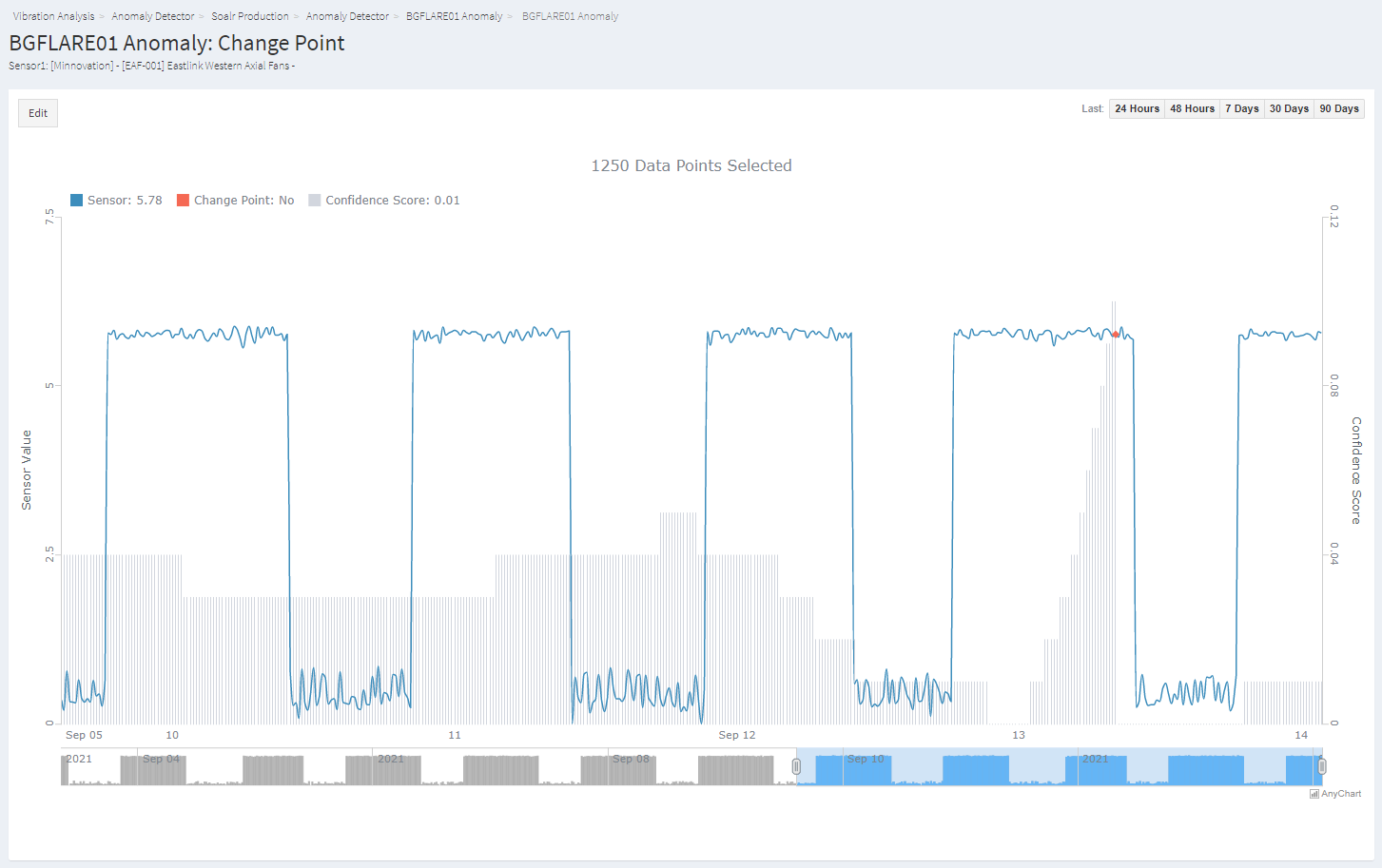

Data Analysis

Get access to a variety of powerful statistical and business intelligence tools that anyone can use. Empower everyone in your teams to hunt down and resolve potential problems. Users are guided through workflows to train data, compare results of their models, and rate the performance of similar assets of the same type, and view the effects of alerts all without needing to call on the IT department or write a single line of code.

“With the combination of real time data logging and leading indicators, issues with any of our equipment can be detected and rectified before it becomes a compliance issue”

Dale Grixti, RunEnergy

Case Studies

Frequently Asked Questions

Users select the data set/s they are most interested in, decide on their outcome they want and click the continue. AlphaX takes the hard work out of training and testing models by automatically selecting the best algorithms to fit the data you are exploring. Predictions and anomalies are detected using unsupervised machine learning techniques that are generally unlabelled datasets.

AlphaX is easy to use. The platform is filled with guided tutorials to make the process of creating, maintaining and analysing data a simple process. In this way we open up the world of data science to not only IT and specialists but to your entire team in a consistent and reliable way without needing to write a single line of code!

Generally speaking the more data that you have available the better your predictions will be. That said, it varies, some AlphaX predictive tools have a maximum of 4096 intervals and others have a much larger limit – while this isn’t a definitive answer – think the more complex the event you are trying to predict, the more data you will need.

The business should have knowledge of and a clear understanding of the problem. They should understand the impacts it has on their business and be able to make the necessary changes to existing business processes to help collect the right data to proactively identify the problems before an event takes place.